Our previous projects: over the years, we have installed a wide range of equipment, from gluing machines to large wood dryers and finger jointing lines.

Here are some of our larger projects:

2022 - WDE Maspell vacuum kilns for Standwood

Standwood is an Estonian company that manufactures sauna construction materials from both heat-treated and untreated wood, focusing on improving durability and quality. The company uses WDE Maspelli's patented vacuum technology-based thermal ovens, which can process wood at temperatures of up to 215 °C using only water vapor and heat, avoiding the use of chemicals. As a result of thermal treatment, the wood's resistance to moisture and mold increases, the wood becomes darker, and deformation due to environmental effects of the wood is reduced.

Source: WDE Maspell, 2021

The annual processing capacity of the new thermal furnaces is 6,000 m³, which is added to the previous capacity of 3,000 m³, bringing the total capacity to 9,000 m³ per year. The process takes 36–48 hours, and connecting the chambers into a single system allows the residual heat generated during the cooling phase to be used to heat the second thermal chamber, significantly reducing the energy consumption and CO₂ emissions required to process one cubic meter of wood.

2021 – System TM optimization and finger jointing line and Termolegno dryers in Barrus

Source: System TM, 2022

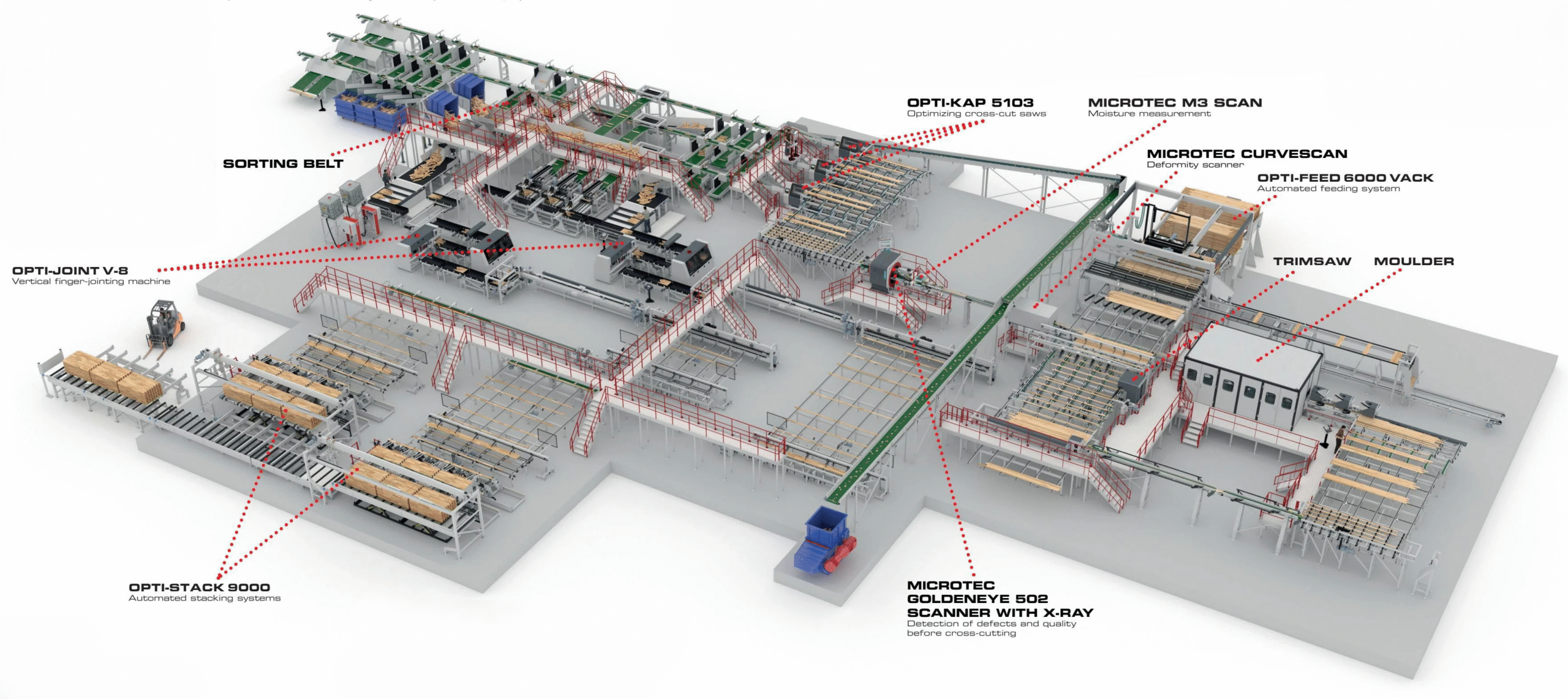

In 2022, Barrus, one of Europe's largest manufacturers of glued wood components, launched an optimization and finger jointing line supplied by our partner System TM.

The finger jointing line operates on a demand basis, allowing Barrus to focus on the products that are currently in demand. The finger jointing line is designed for high flexibility and productivity based on the just-in-time principle. At the beginning of the line, the sawn timber packages are lifted onto a chain conveyor, where the Opti-Feed 6000 VACK lifts the material from the packages layer by layer onto the conveyor, removing the spacers.

The MiCROTEC Curvescan measuring system then checks the curvature of the details, the moisture content is measured with the MiCROTEC M3 moisture meter, and the wood is scanned with the MiCROTEC Goldeneye 502 scanner. All data is compiled to ensure accurate sorting before gluing.

The workpieces are cut at the required locations using three Opti-Kap 5103 optimization saws. The software determines the cutting points to maximize material utilization. Cut-out pieces with defects are removed and suitable workpieces are forwarded to finger jointing.

The line includes two Opti-Joint V-8 high-performance vertical finger jointers that glue the edged boards together end-to-end. After gluing and pressing, the finished parts are sent to two Opti-Stack 9000 stackers, where they are either packed in full length or divided into shorter blocks for further processing.

The entire system is fully integrated and automated, allowing Barrus to quickly switch between different products while reducing labor costs and maximizing material utilization. This enables Barrus to respond flexibly to market demands and achieve high production efficiency.

Source: Termolegno, 2025

By the end of 2021, a total of 12 Termolegno wood dryers had been installed at the Barrus production site.

2019 – Kallesoe radio-frequency press and REX planers at Palmako Kavastu beam factory

The Palmaku Kavastu factory began producing glulam timber in 2007 to supplement Palmako's production of garden houses, saunas, and other wood products with its own material. In 2017, it was decided to replace the entire aging glulam line with a completely new, modern production line, with a primary focus on flexible product changeover. Several top-level equipment manufacturers contributed to the project, including Kallesoe with radio-frequency presses and REX with planers. The new line allows for flexible production of both large quantities and small batches of products: glulam, duo and trio beams, KVH, and log house lamellas.

Source: Kallesoe, 2019

The Kallesoe Vario press enables fast and energy-efficient gluing, as radio-frequency technology only heats the glue line, meaning that pressed products do not require a curing buffer and can immediately move on to the next processing stages. A special feature of the press is its ability to process a wide range of dimensions: lengths from 4 to 18 meters, thicknesses from 60 to 240 mm, and widths up to 1260 mm. The press is also flexible – parts of different lengths can be processed in a single cycle, and the dimensions can be changed quickly thanks to the semi-automatically adjustable side plates. Per shift, the annual productivity of the press is up to 32,000 m3.

The initial processing of the lamellas is carried out using the automatic REX Bigmaster, which allows all product settings to be made outside the soundproof booth and without interrupting the production process. The REX Supermaster is used for finishing the final products. It adapts to a wide variety of cross-sections and dimensions, working with sufficient force on large beams, but gently and precisely on smaller details. The combination of these machines makes Palmako's production significantly more flexible than before, allowing for the efficient manufacture of both large series and individual orders.

Source: Kallesoe, 2019

Our customers