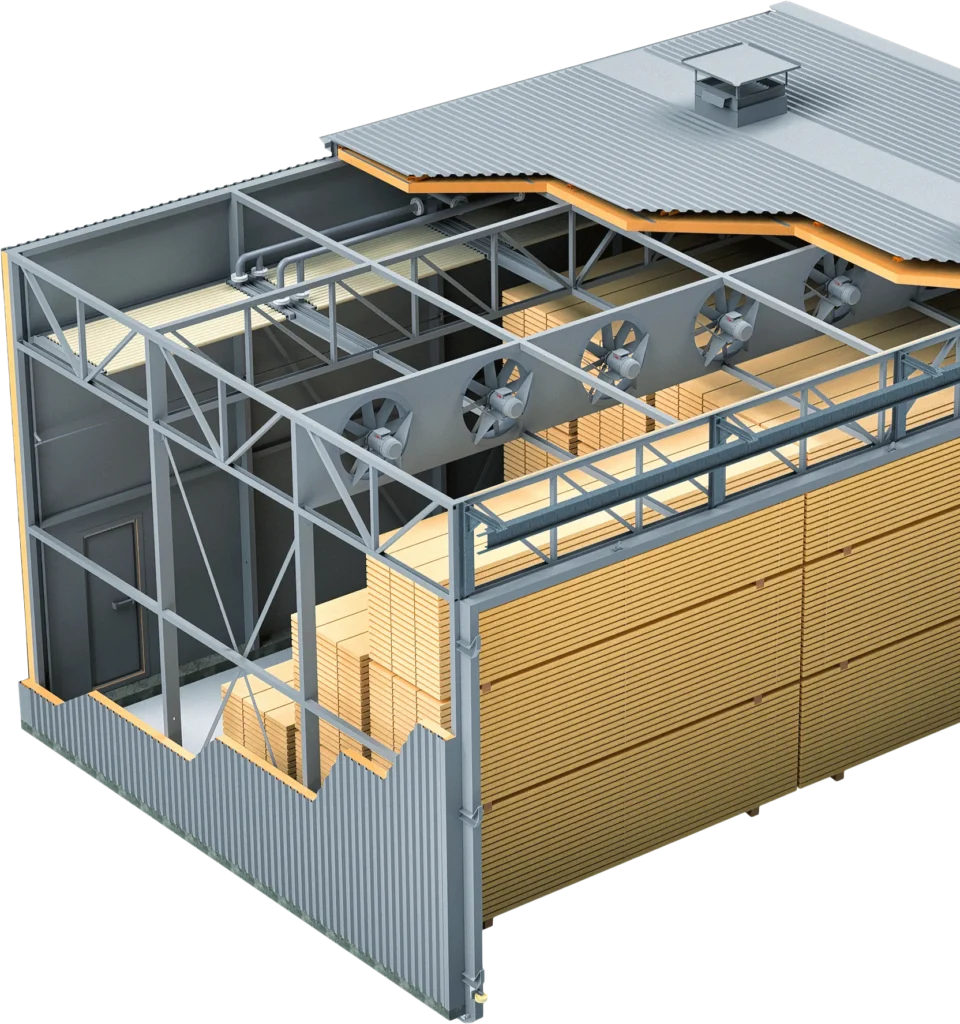

Thermolegno's strength lies in its tailor-made solutions for woodworking equipment, particularly in the field of drying and steaming kilns. Each system is designed according to the customer's specific needs - taking into account the characteristics of the wood to be processed, operating cycles, production volumes, local energy sources, and environmental conditions - with the aim of ensuring maximum energy efficiency. All Termolegno kilns are 100% made in Italy - in the Termolegno factory in Rauscedos, Friuli Venezia Giulia.

Drying wood in a controlled environment significantly reduces the environmental impact: the amount of waste wood is 30-50% lower than in natural drying. This results in less waste and less deforestation. In addition, the process speeds up considerably, which ensures better productivity in the wood processing industry.

Termolegno convection drying kilns:

- Modular front-loading or tunnel kilns;

- Pre-drying kilns;

- Steaming kilns;

- HT drying kilns for ISPM15 heat treatment;

- Combined drying kilns;

- Continuous drying kilns;

- High energy efficiency drying kilns